How to Escape Firefighting in Supply Chain Teams

How to stop firefighting in your supply chain and lead differently beyond Excel chaos and Teams messages.

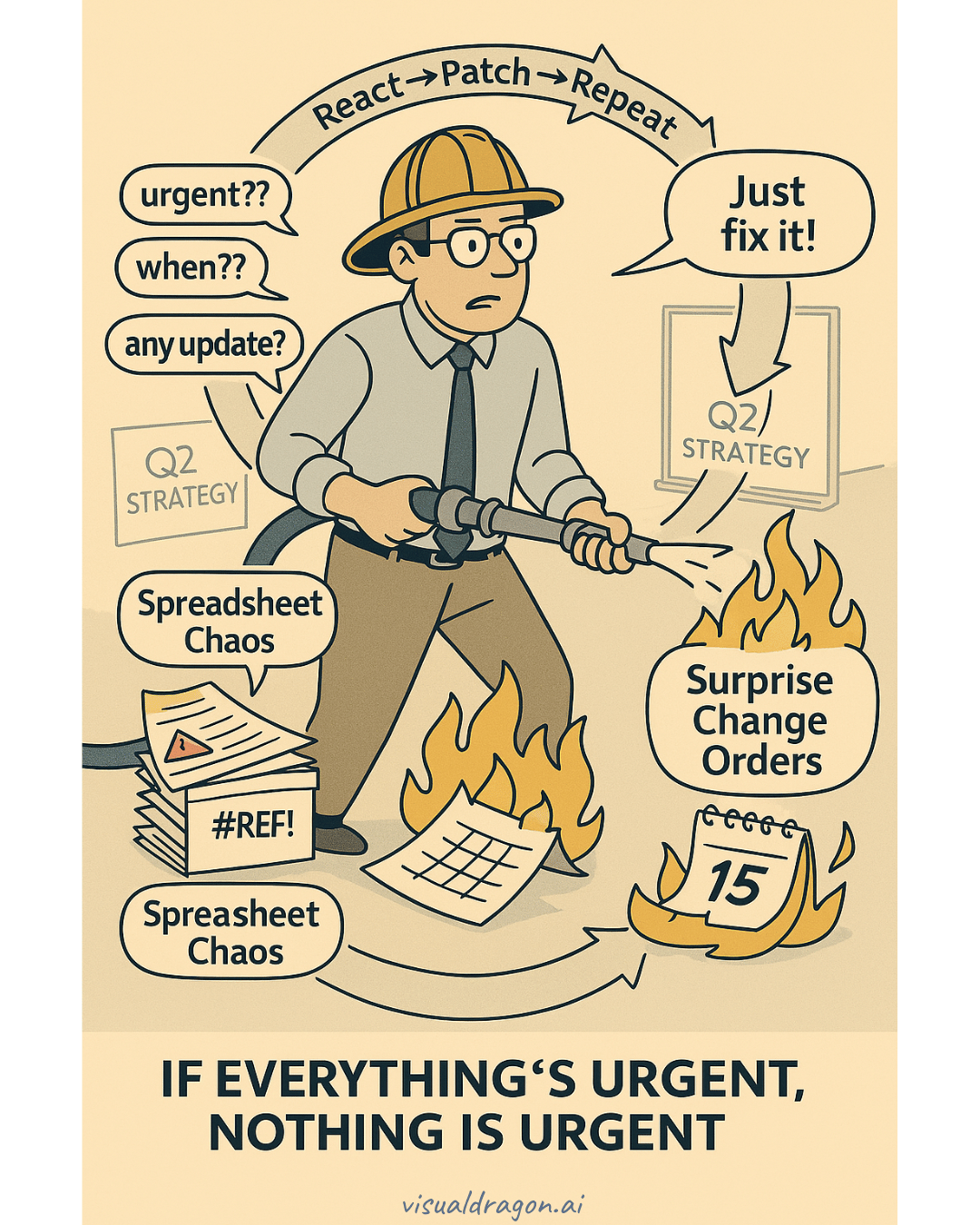

Firefighting in supply chain teams often looks like this:

You open your laptop to a flood of Teams messages. Someone needs help tracking down a shipment. An Excel file needs updating. There’s a new “urgent” request from leadership. You jump in again because you're the go-to person. You’re solving problems, putting out fires, and running on adrenaline.

At the end of the day, you’ve worked nonstop, but nothing moves forward.

This cycle of firefighting, Excel updates, and reactive coordination isn't just exhausting. It's a sign that something in the supply chain planning process is broken. And if you’re living this every day, it’s not a personal failing. It’s a structural one.

Table of Contents ▶

How We Got Stuck in Survival Mode And What It’ll Take to Break Free

Globally, across factories, warehouses, and planning offices, supply chain teams are waking up to the same déjà vu.

The same scramble.

The same last-minute fixes.

This slowly became the supply chain operating model

Let’s Be Honest—We’re Not Planning. We’re Firefighting.

Leadership teams like to call it “being agile.”

We frame it as we move when the market moves

But let’s call a spade a spade: reactive, unsustainable, and exhausting.

Our best people aren’t solving problems—they’re putting out fires.

They’re digging through Teams chats, emails, juggling outdated Excel sheets, and praying for clean data.

They’re spending more time chasing than planning.

And that’s taking a toll on performance, morale, and talent retention.

The Hidden Cost of Supply Chain Firefighting

Here’s what doesn’t show up in your dashboards:

- The late-night expedites you didn’t budget for.

- The safety stock you carry “just in case.”

- The quiet burnout that leads great planners to quit.

- The wasted hours reconciling spreadsheets instead of solving root issues.

We normalize it because it feels like we’re doing something. But all we’re doing is spinning faster.

That’s not resilience. It’s reactive muscle memory.

Why Excel fuels firefighting in Supply Chain

Nobody will deny that Excel is amazing. It’s flexible, familiar, and fast. But it was never meant to run an end-to-end supply chain.

The problem isn’t the tool—it’s what it represents:

• A lack of system trust.

• A patchwork of manual fixes.

• A reliance on tribal knowledge.

And when we back it all up with endless Teams pings and one-off workarounds, we’re not building collaboration. We’re building chaos that no one can see.

Why “Digital Transformation” Alone Won’t Save You

Too many companies have spent millions on platforms, only to end up right back in Excel.

Why?

Because they focused on the tools, not the mindset.

They tried to digitize dysfunction instead of rethinking how they work.

They added tech without changing behavior.

And so they stay stuck in Phase 1—busy, burned out, and not getting better.

Mindsets need to change. Not Just Systems

This isn’t a pitch for another platform. It’s a call for a different way of thinking.

As leaders, we need to ask:

- Why are our best planners spending 80% of their time formatting spreadsheets?

- Why do we celebrate heroics but overlook the root causes?

- Why do we treat firefighting as inevitable, instead of a sign that something’s broken?

It starts with choosing a better normal.

• One where visibility isn’t a daily scavenger hunt.

• Where Teams messages don’t double as crisis command centers.

• Where your team has time to think ahead, not just react.

Final Thoughts

Your people didn’t sign up to be human middleware between broken systems.

They want to make an impact. To fix things. To move the needle.

But we can’t ask them to do that while we keep them buried in spreadsheets and ping storms.

This is your moment—not to buy another tool, but to lead a mindset shift.

To stop normalizing firefighting.

To stop mistaking busyness for effectiveness.

To build something more human, more resilient—and frankly, more sane.

Let’s stop the cycle.

Start looking at the fire and work backwards on how it can be prevented

TL;DR Firefighting in Supply Chain

What is firefighting in Supply Chain?

It refers to the constant reactive handling of issues due to poor planning, misalignment or system trust (aka dirty data)

How can teams reduce firefighting?

- Focus on the root causes of 'fire'. Every 'fire' is a golden learning opportunity

- Clean data to build trust in data systems

- Shift from reactive to proactive planning strategies

Why is Excel commonly used despite its limitations

It is familiar, fast and at no additional cost to most organizations. Over-reliance often reflect deeper process and data gaps.