The Real Cost of SKU Complexity: Why Brands Must Simplify

Discover how SKU complexity drains profits and learn strategies to streamline operations for scalable growth

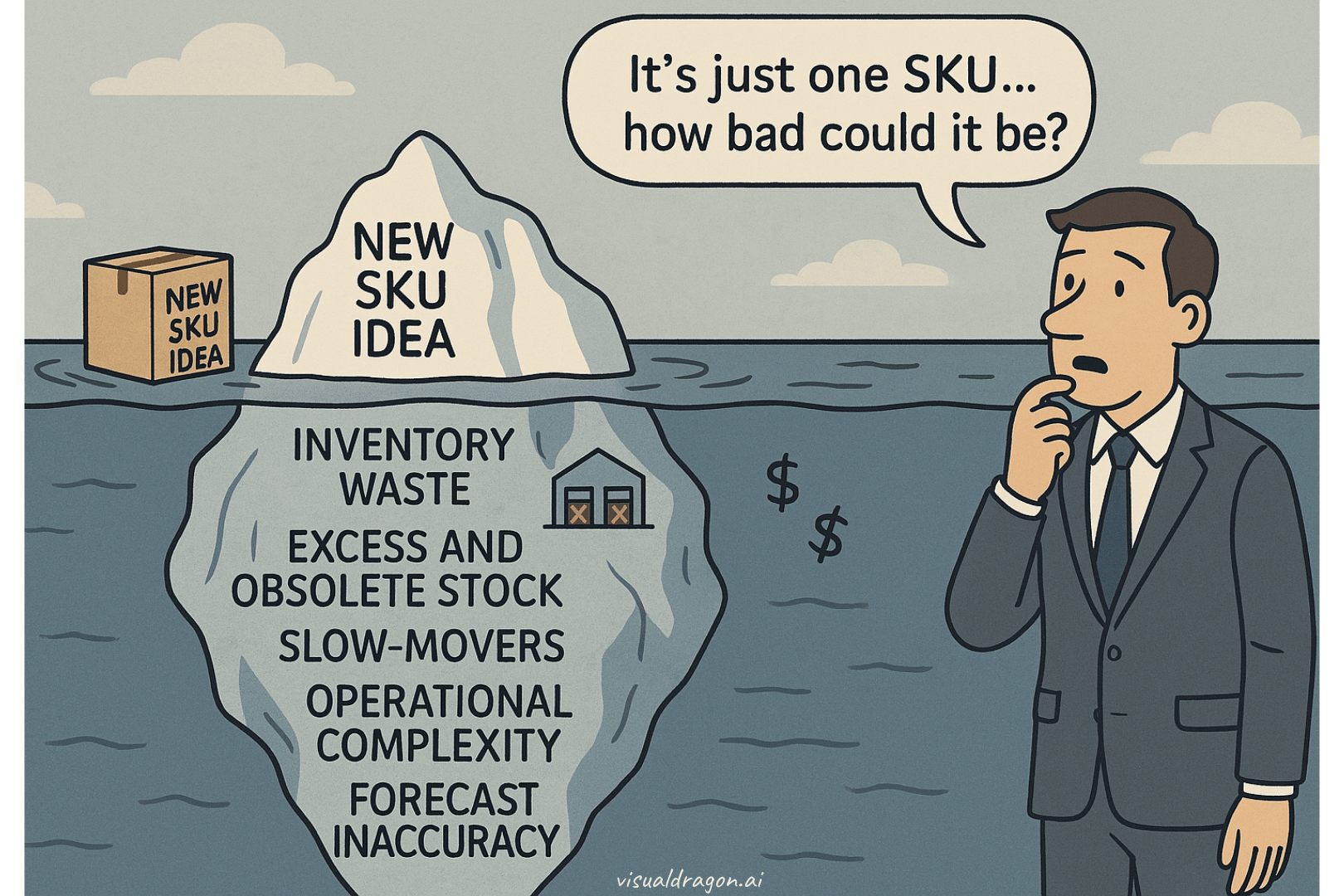

“More SKUs means more choice. That’s what customers want… right?”

That’s the logic most growing brands follow. And to be fair, it’s not entirely wrong—at first. You add a few new products, sales increase, and things look great

But if you don’t manage it intentionally, SKU growth becomes silent sabotage.

Behind the scenes, your inventory bloats. Forecasts become unreliable. Fulfillment slows down. Margins quietly erode. And suddenly, you’re doing more to earn less.

If you're a mid-sized company scaling fast, this article is your guide to identifying the hidden costs of SKU complexity, diagnosing the symptoms, and developing scalable solutions

Why SKU Complexity Is More Dangerous Than It Looks

Here’s what happens when SKUs multiply without strategic controls

1. You’re Sitting on Inventory That Doesn’t Move

Every new SKU you add needs inventory coverage. Even if it's just a few units, scale that across dozens of low-selling SKUs, and suddenly, you're sitting on piles of slow-moving or obsolete stock.

Why it hurts:

- Ties up working capital that could fund growth

- Creates space constraints in your warehouse

- Leads to markdowns or write-offs when products expire or fall out of favor

In most businesses, 5% of SKUs drive less than 1% of sales but consume 20–40% of inventory value. That’s a silent drag on your balance sheet.

2. Your Forecasting Gets Fuzzier

Forecasting right is hard. Now imagine trying to predict demand for 200 slow-moving SKUs where some of it are new, seasonal or erratic. The odds are that you will be more wrong than right.

Why it hurts:

- Inaccurate forecasts lead to either stockouts or excess

- “Phantom demand” from over-forecasting leads to unnecessary purchasing or production

- Under-forecasting can kill availability on your better products when resources are tied up elsewhere

Best-in-class teams use family-level forecasting—forecasting demand at a group level and allocating to individual SKUs—to reduce error and volatility.

3. Your Warehouse Team Is Wasting Time

A bloated SKU catalog complicates every part of warehouse ops. Workers take longer to find and pick products. Storage is disorganized. Errors go up. Labor costs creep in.

Why it hurts:

- Slower order fulfillment leads to missed SLAs or customer frustration

- Higher risk of mis-picks or packing the wrong item

- Increases labor cost per unit shipped

Warehouses thrive on simplicity. Frequent SKU slotting audits and velocity-based storage layouts can dramatically improve productivity.

4. Your Planning Team Is Stretched Thin

Planning for 100 SKUs is manageable. Planning for 600, many with low demand, unpredictable lead times, and small batch sizes? That’s a nightmare.

Why it hurts:

- Procurement becomes fragmented (more suppliers, smaller POs)

- Production needs more line changeovers and cleanup time

- Logistics requires more coordination and partial loads

Effective planners use MOQ rationalization and SKU harmonization strategies like bundling or modular designs to reduce planning effort and improve efficiency.

5. Your Margins Are Quietly Eroding

Here’s the killer: all that complexity adds cost. It’s not always obvious, but it hits your margins from every angle—purchasing, freight, warehousing, labor, even customer support.

Why it hurts:

- Smaller orders → worse supplier pricing

- Partial shipments → higher freight cost per unit

- Slower inventory turns → more capital tied up

- Margin mix worsens when slow-sellers take up operational bandwidth

We recommend building a “Cost-to-Serve” model per SKU. When you look at the product's true cost across its lifecycle, you’ll often find that many SKUs are unprofitable even if they technically generate revenue.

The SKU Complexity Health Check

Want to know if your business is quietly bleeding margin from complexity?

Ask yourself these five questions:

| Ask Yourself This | Why It Matters |

|---|---|

| Are 20% of SKUs driving 80% of your sales? | The rest may not justify the cost. |

| Is inventory aging faster than sales velocity? | You’re holding too much of the wrong stuff. |

| Are you forecasting individual low-volume SKUs? | High error = high waste and firefighting. |

| Is your warehouse struggling with space or picking speed? | SKU sprawl is usually the culprit. |

| Are your gross margins flat or declining while SKU count grows? | That’s complexity eating your profit. |

What To Do About It: Moves to Control SKU Complexity

If you’ve spotted warning signs, here’s what you can do—without sacrificing growth or customer choice.

1.Segment and Prioritize Your SKUs

Don’t treat all products the same. Use a mix of:

- ABC Analysis (based on revenue contribution)

- XYZ Analysis (based on forecastability)

Assign stocking and service policies accordingly:

- “A/X” SKUs → high availability

- “C/Z” SKUs → maybe made-to-order or eliminated

2. Simplify Forecasting with Product Families

Instead of forecasting 100 niche variants, forecast the parent group and allocate down using historical ratios. This improves accuracy while still guiding supply planning.

Use tools like:

- Demand classification (smooth vs. intermittent)

- Forecast CoV (Coefficient of Variation)

- Aggregate-level forecasting models

3. Re-slot Your Warehouse Based on SKU Velocity

Your pick path should prioritize fast movers. Every 6–12 months, run a warehouse audit:

- Reassign bin locations based on SKU turns

- Move dead stock out of prime picking areas

- Consolidate slow movers in lower-cost storage zones

4. Build a Cost-to-Serve Model

Map the true cost of each SKU by including:

- Supplier costs (including premiums for low volumes)

- Inbound and outbound logistics

- Storage, labor, and handling costs

- Capital cost of inventory

You may find certain SKUs are not just low-margin but net-margin negative.

5. Adopt Clear Rules for Adding (and Killing) SKUs

Set guardrails for product expansion:

- Is there projected demand above X units/month?

- Will it cannibalize another SKU?

- Can it ride existing supply/warehouse flows?

And just as importantly, set kill criteria for underperforming SKUs before they rot in inventory and quietly tank your ROI.

Final Thought: Simplify to Scale

SKU complexity is a silent cost. It doesn’t scream. It seeps.

But if you’re scaling, managing SKU variety proactively is one of the best things you can do to protect your margins, your team’s sanity, and your ability to serve customers fast and well.

- Start with a portfolio diagnostic.

- Build inventory policies, not just products.

- Scale with focus, not clutter.

- Kill products when the true cost doesn't make sense any more

Want help identifying your SKU complexity hotspots or modeling cost-to-serve? Drop us a message